Dafram Ball Valve Identification & Supply Support

Identify Dafram ball valves from tag plates, cast markings, and dimensions — and source replacements.

How to Identify a Dafram Ball Valve

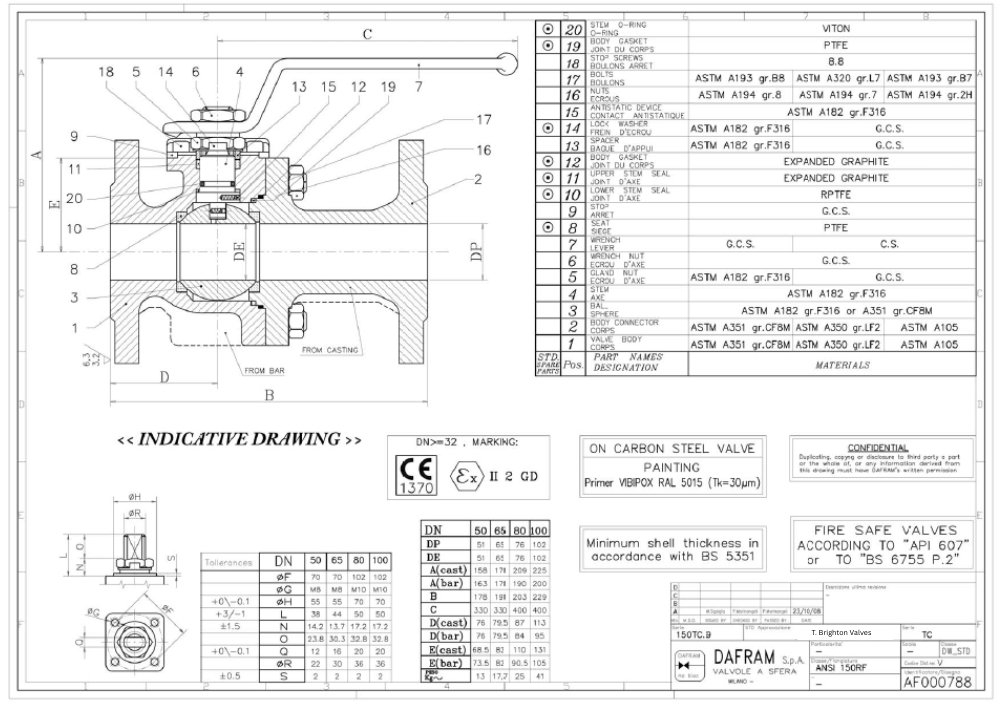

Dafram ball valves can usually be identified from a combination of body markings, dimensions, and — where fitted — tag plate information. (Or, a datasheet like in the image to the right/below!)

On older installations, tag plates may be missing or were not supplied, so identification often relies on the valve body itself.

Cast or stamped markings may include:

- DAFRAM name or logo

- Nominal size (e.g. DN50, 2″)

- Pressure rating (e.g. PN40, Class #150)

- Material or heat/casting numbers (e.g. CF8M, WCB)

- These marking are often the most reliable identifiers on older or inherited valves.

Some Dafram valves are supplied with tag plates:

If present…

- these can typically be found on the end connections: the flange rim or nearer the welded end.

- They may show:

- Model or series

- Size and pressure rating

- Body / trim materials

- Applicable standards e.g. API 607 (Fire safe)

- If not present, casted / stamped details are more likely.

Without paperwork, tags or cast/stamped markings, the following dimension and construction details are most useful:

- End connections (flanged / threaded / welded)

- Face-to-face length

- Body style (1-piece / 2-piece / 3-piece)

- Reduced or full bore

- Presence of ISO 5211 direct mount pad (if actuated / gearbox)

If markings are unclear or incomplete, clear photos of the valve body, ends, and overall construction are usually sufficient to confirm the specification.

Email photos for identificationCommon Dafram Ball Valve Types & Configurations

Dafram manufacture a range of ball valve designs for different pressure classes, materials, and applications.

The configurations below reflect commonly encountered Dafram ball valve constructions.

Replacement & Supply Support for Dafram Ball Valves

Dafram ball valves are commonly installed in process, industrial, and OEM applications, where long service life and dimensional consistency are important.

Where a Dafram valve requires replacement or additional units are needed, we can assist by:

- Confirming the existing valve specification from markings, dimensions, or photographs

- Checking body construction, materials, bore type, and end connections

- Reviewing seat materials and pressure class where relevant

- Advising on direct Dafram supply or technically equivalent alternatives, depending on availability and application

Where original documentation is unavailable, identification is typically based on physical characteristics and dimensions, rather than paperwork alone.

The objective is to maintain functional and dimensional equivalence, avoiding unnecessary changes to pipework or actuation wherever possible.

What to Send for Identification or Quotation

To help identify or supply a Dafram ball valve, engineers typically provide one or more of the following:

- Photographs of the valve body and ends

- Any tag plate or stamped markings, where present

- Nominal size and pressure class, if known

- Basic service information (media, pressure, temperature)

- Actuation details, where applicable

Full datasheets are not required to start the process.

In many cases, clear photographs alone are sufficient to confirm the specification.